Pumping station refurbished:

Underground use

There is a lot going on in the Alster metropolis, and not just on the surface.

Hamburg Wasser recently repaired two massive sewage pipes around 25 metres below the Süderelbe. At the same time, we refurbished the pumping station in Harburg.

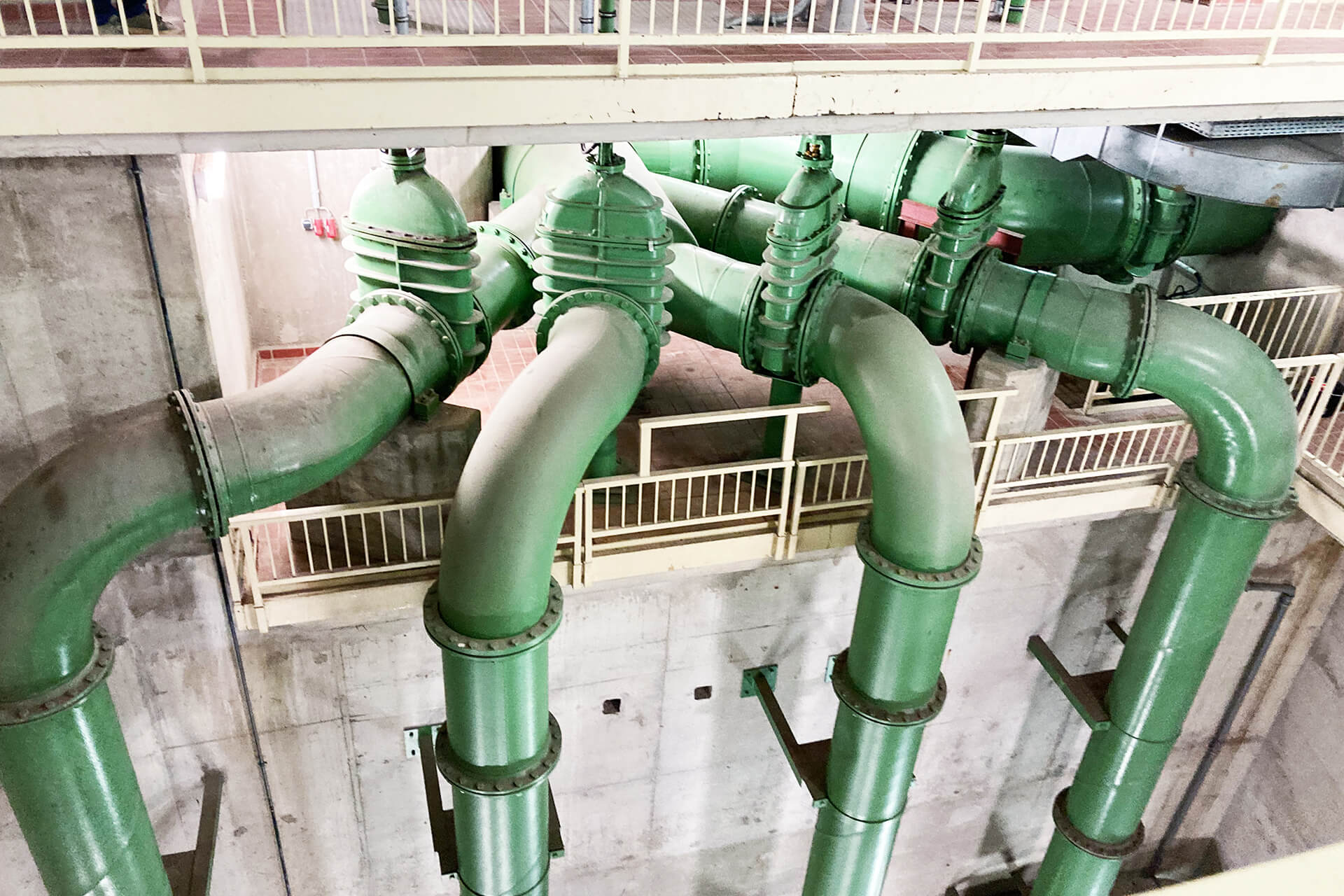

The little house of the pumping station on Harburg main dyke is inconspicuous. But once you enter, an impressive underworld opens up. Imposing green pipes and cream-coloured spiral staircases rise 22 metres into the depths. There they encounter four 1,040 hp pumps. Over the past year and a half, this has often been the location for a few of our Hamburg teams.

Their task: to overhaul the entire control technology of the wastewater pumping station. To this end, they completely renewed a total of 20 control cabinet panels, including the necessary PLC components. The general electrical installation, including cabling, lighting, switches and sockets, as well as the safety lighting, were also partially renovated to make them fit for their demanding use in the wastewater system.

“In the pump sumps, all system components must be explosion-proof due to the gases. They are also subject to severe corrosion. These special requirements also had to be taken into account when selecting the materials,” says Christian Liebelt, Commercial Manager at our Hamburg site, adding: ‘We were able to prevail in the tendering process because we have experienced colleagues in this very specific field. Hamburg Wasser also wanted to have someone on site for the downstream services who could react quickly in the event of a malfunction.”

Our task: A retrofit of the entire control technology to ensure that the wastewater network can be relieved in an emergency by pumping it into the Süderelbe.

Working in the wastewater network not only puts a strain on the material. The team on site reports that, in addition to the confrontation with typical wastewater residues and corresponding odours, the narrow access hatch is also a small challenge. In certain areas, our colleagues had to carry gas detectors with them due to the risk of explosion, because some gases, like carbon monoxide, are odourless.

“Some of the removal and installation work was carried out in late shifts, sometimes even at weekends, because the system had to be completely disconnected from the grid for a few weeks,” explains Liebelt. The renovation work is expected to be completed by the end of July. The pumping station is once again optimally equipped for its task. Its purpose is to relieve the oldest sewage network in continental Europe in an emergency by pumping it into the southern Elbe. The emergency is rehearsed once a month with Elbe water.

All parts of the system had to be explosion-proof. We were able to score points here with our expertise in explosion protection.

Christian Liebelt, Commercial Manager SCHULZ Hamburg