Smart tools

for optimising CIP processes and analysing energy and media consumption

#1 CIP-TOOL

ANALYSIS AND OPTIMIZATION OF CLEANING PROCESSES

Optimizing costs and cleaning efficiency is one of the F&B industry’s biggest challenges in the upcoming future. In response to the market needs, we offer a tool designed for quick and cross-sectional analysis of CIP processes.

Based on over 30 years of experience in the industry, the CIP-TOOL supports analysis of the cleaning efficiency and identification the typical bottlenecks and anomalies. Furthermore, the CIP-Tool provides evaluation of the optimization effects..

Benefits

- complete record of the cleaning process

- efficient use of the installation

- optimization of costs and cleaning time

- eco-friendly process due to reduced consumption of cleaning agents

- enhanced product safety

- advanced control of the installation’s hygienic status

Analysis and optimization

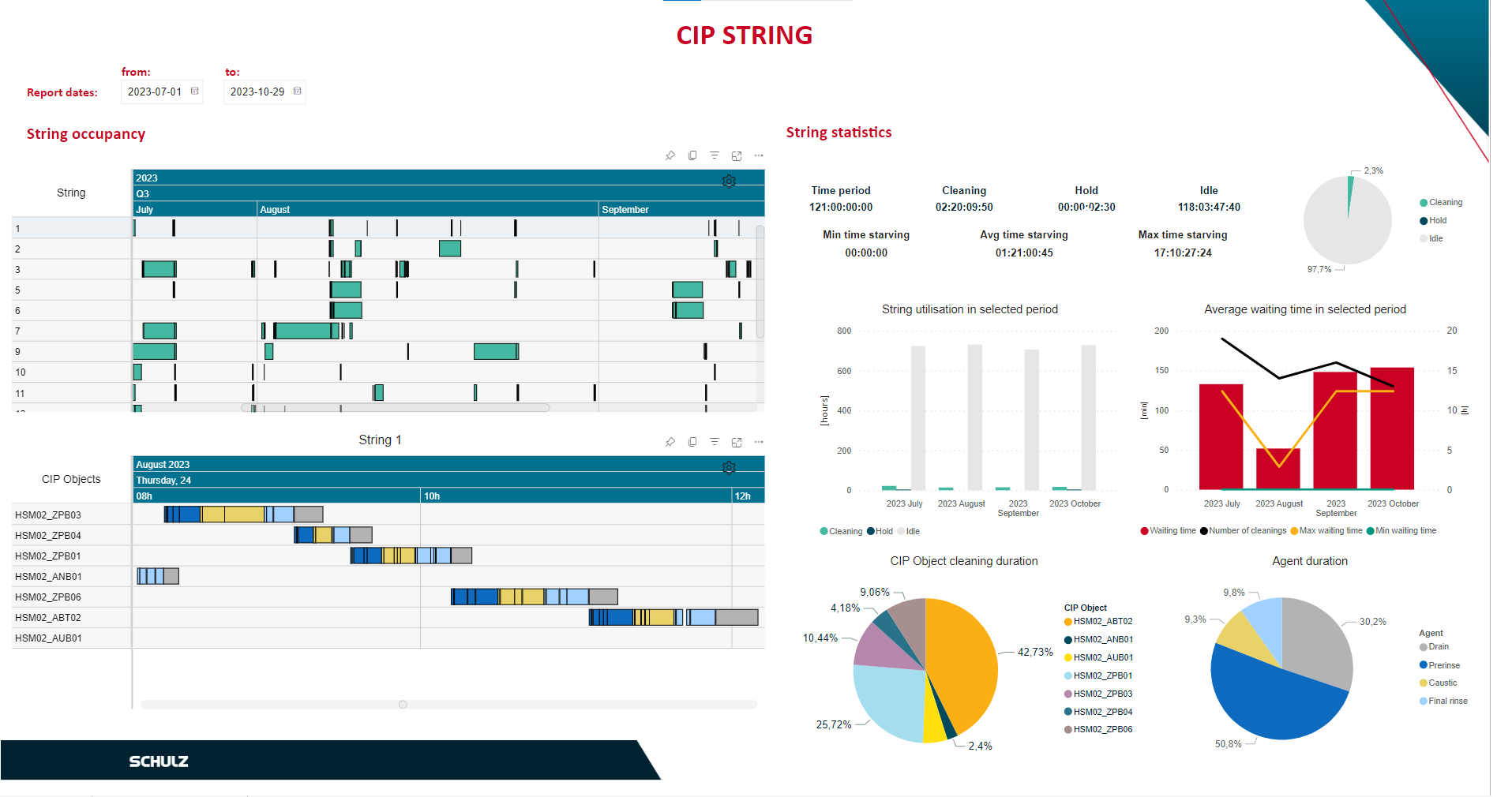

CIP-String

- data analysis from the cleaning loop perspecitve

- graphical presentation of process history

- comparative analysis of data over time

- statistics of loop usage

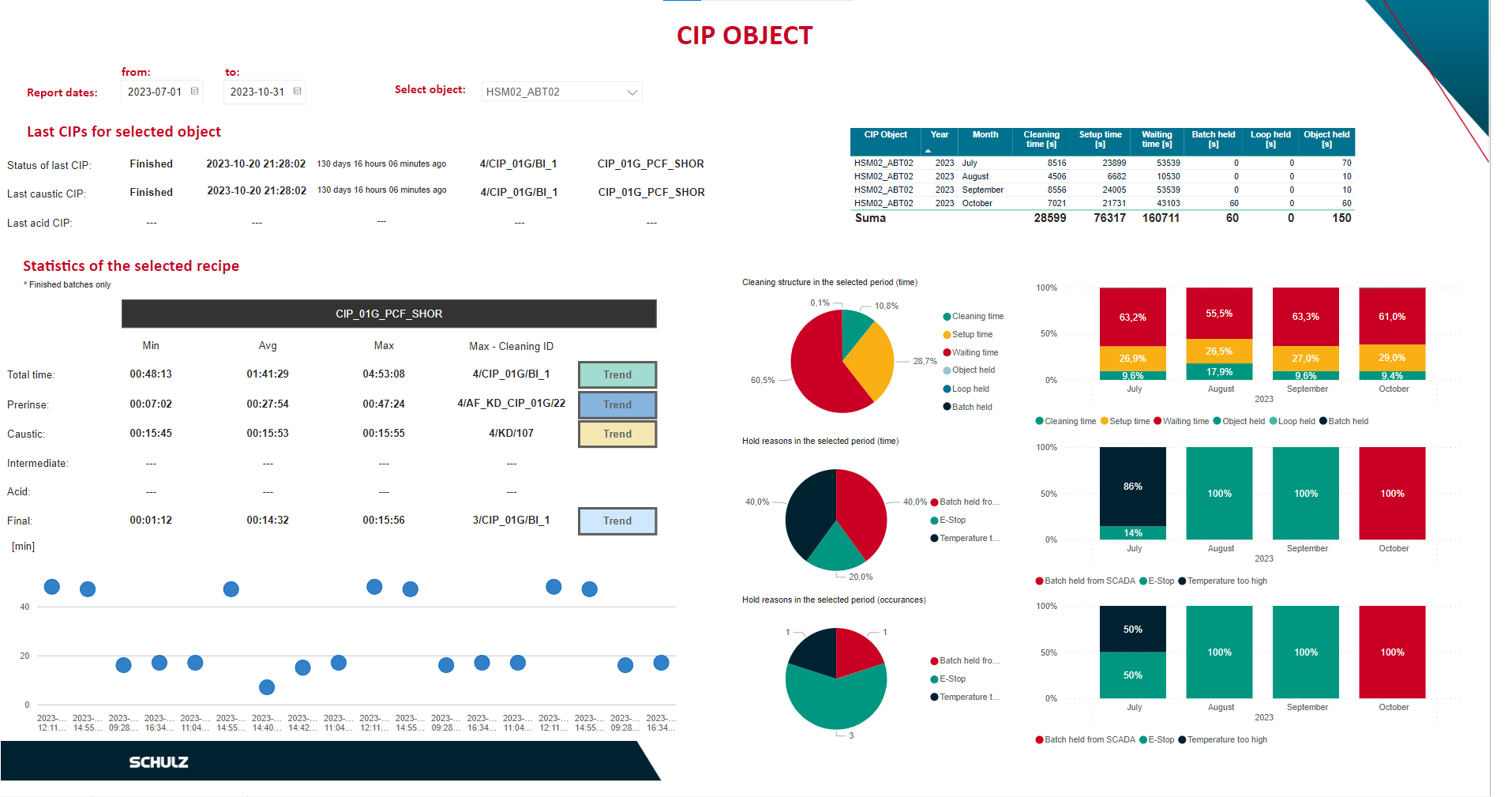

CIP-Object

- data analysis from the object’s perspective

- detailed presentation of the cleaning course

- time-based presentation of change tendencies

- cause analysis of cleaning inefficiencies and their presentation on a timeline

CIP-Set

- key CIP station status information compiled in one place

- cleaning agent parameters analysis during cleaning

- time analysis and prediction of concentrate consumption

- statistics of cleaning agent consumption in relation to cleaning intensity

DECISION SUPPORT

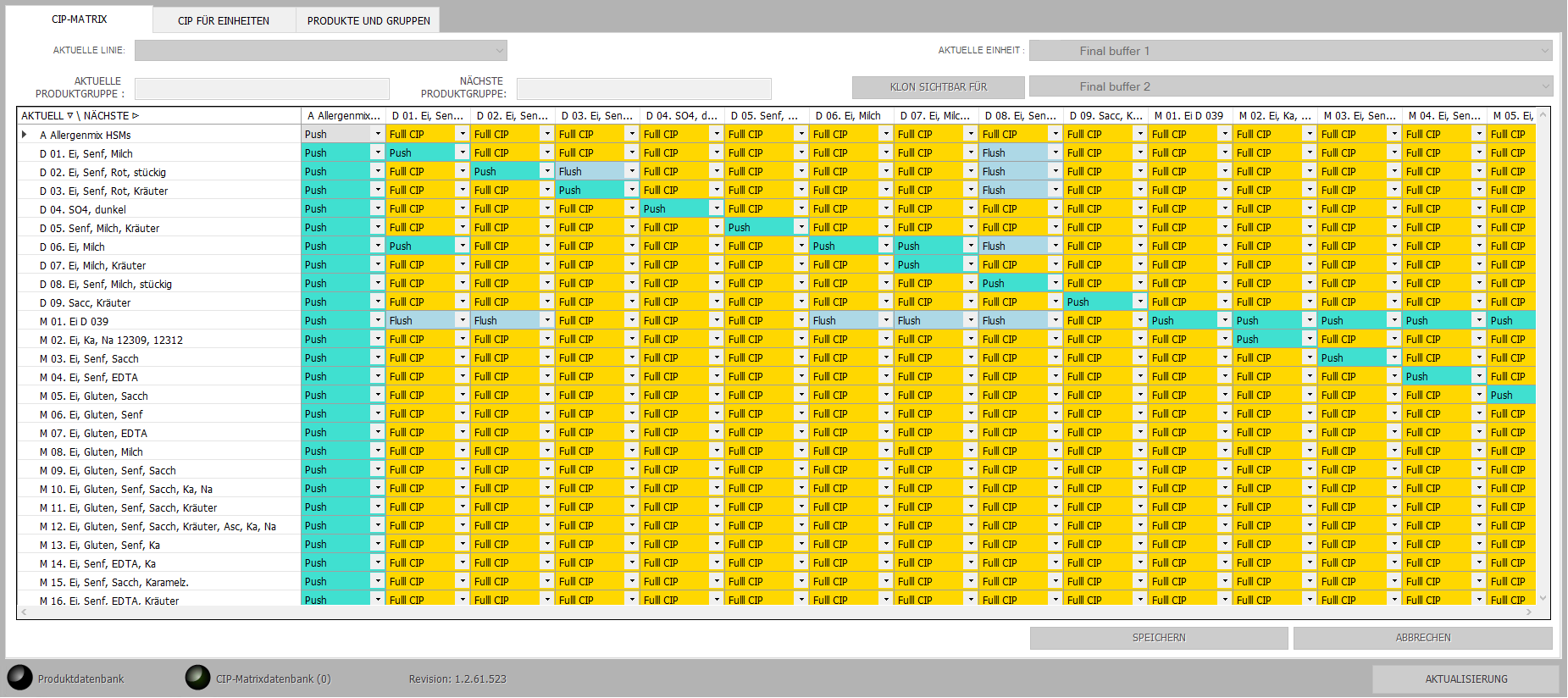

CIP-Matrix / CIP-Selector

- determining the proper cleaning program based on the production order sequence

- suggesting a preferred cleaning program

- automatic override of the proper cleaning program after a product change

- production blocking in case of insufficient hygienic status

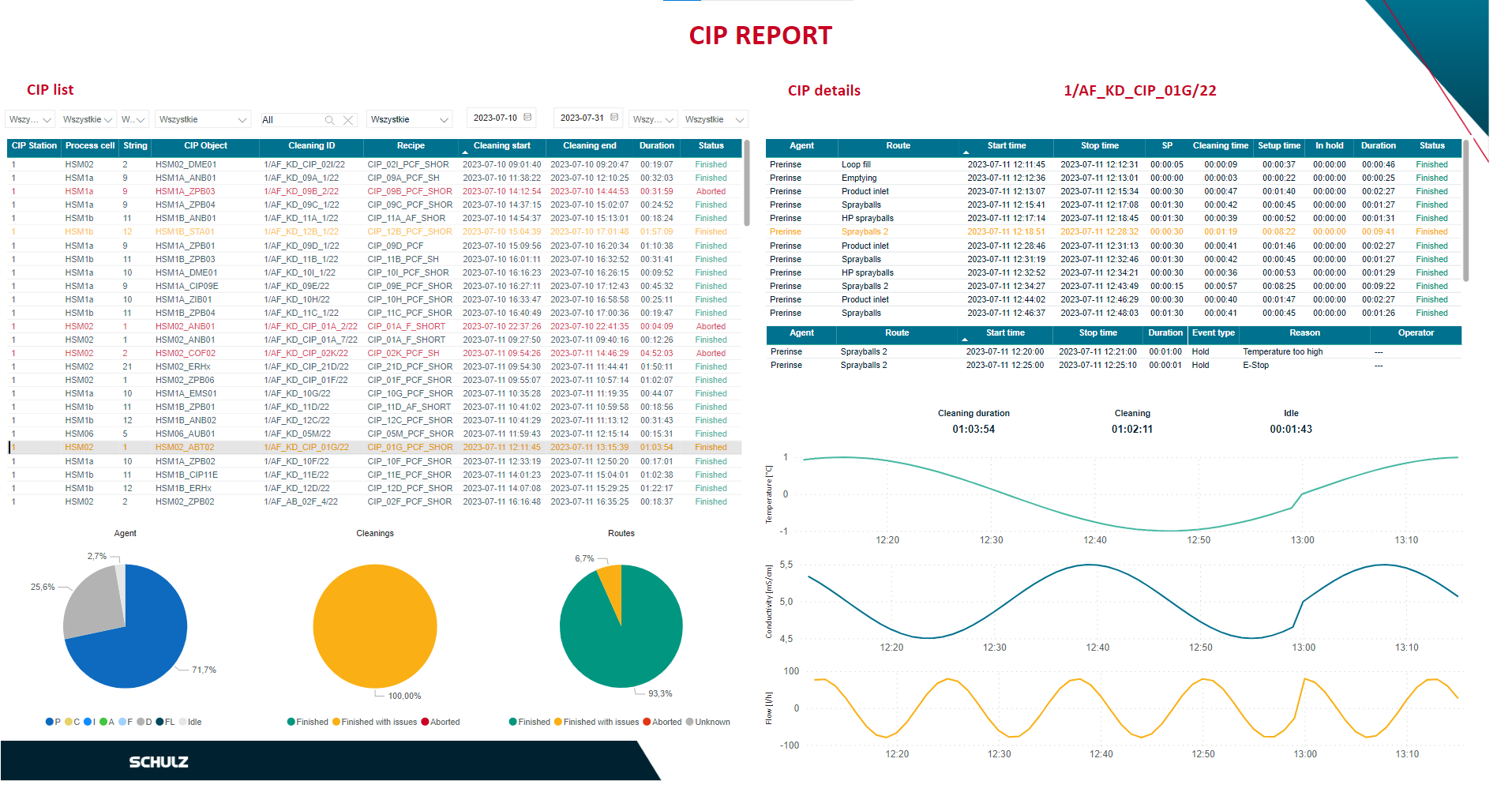

Cleaning process documentation

- cleaning process overview

- intelligent analysis of process characteristics

- highlighting of typical anomalies

- graphical presentation of statistics

- extensive filter system

UNIVERSAL TECHNICAL SOLUTION

- dedicated to many user groups

- applicable to new and existing installations

- Microsoft PowerBI platform – proven and widely used technology

- universal database structure

- integration with SCADA systems

- installation on new or existing computer hardware

- professional support in expanding the existing control system

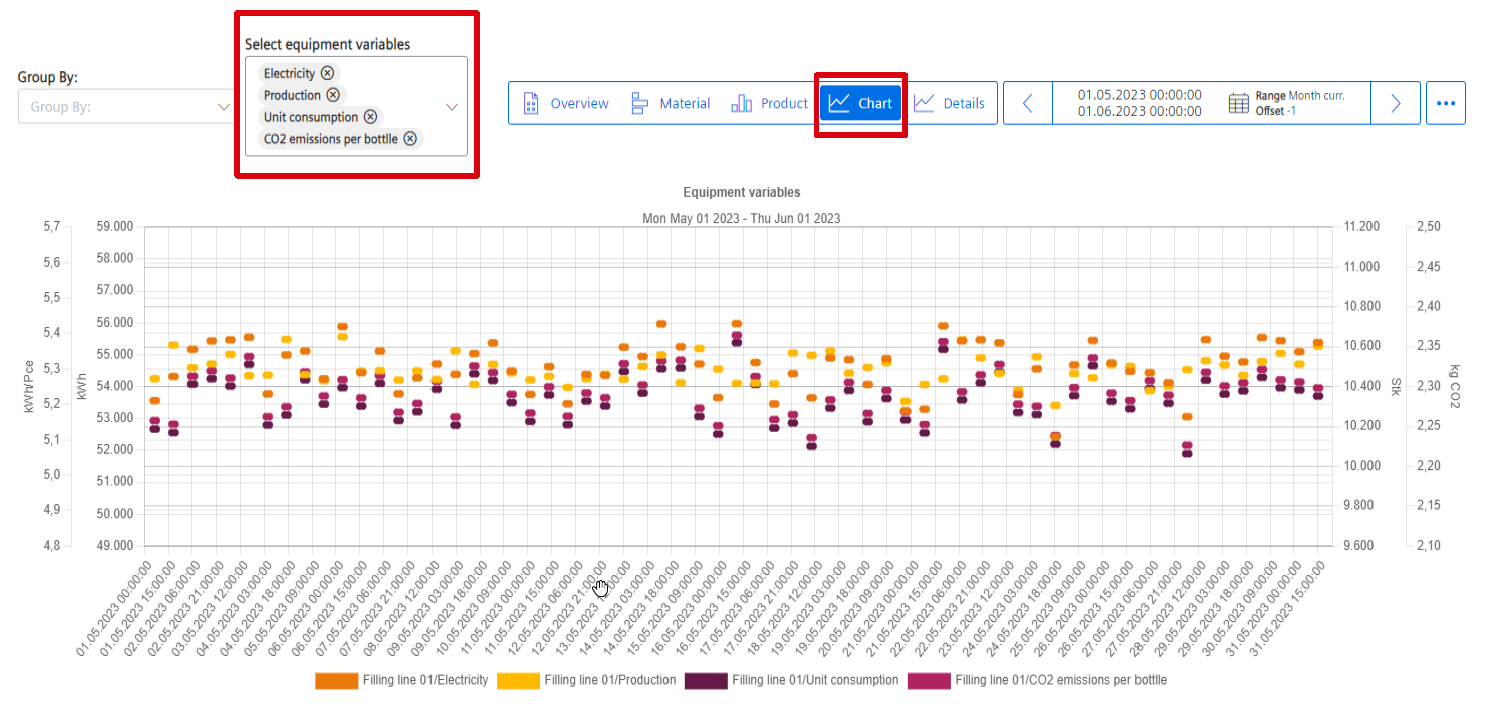

#2 EM-Tool

ADVANCED ANALYSIS OF ENERGY AND MEDIA CONSUMPTION

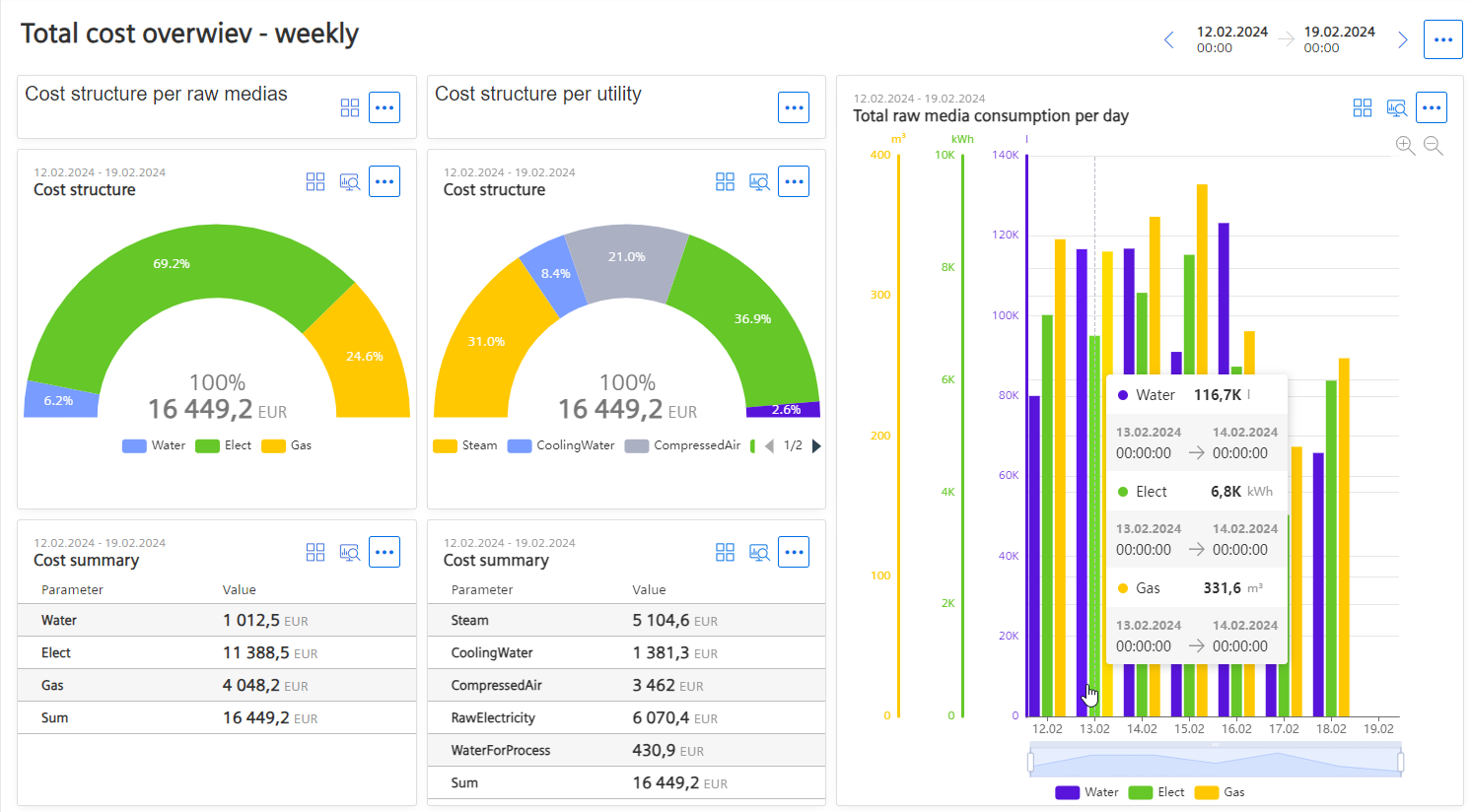

Optimization of production processes, focused primarily on increasing productivity, also includes an attempt to reduce the consumption of electricity and all media required to run production.Produktionsprozessen.

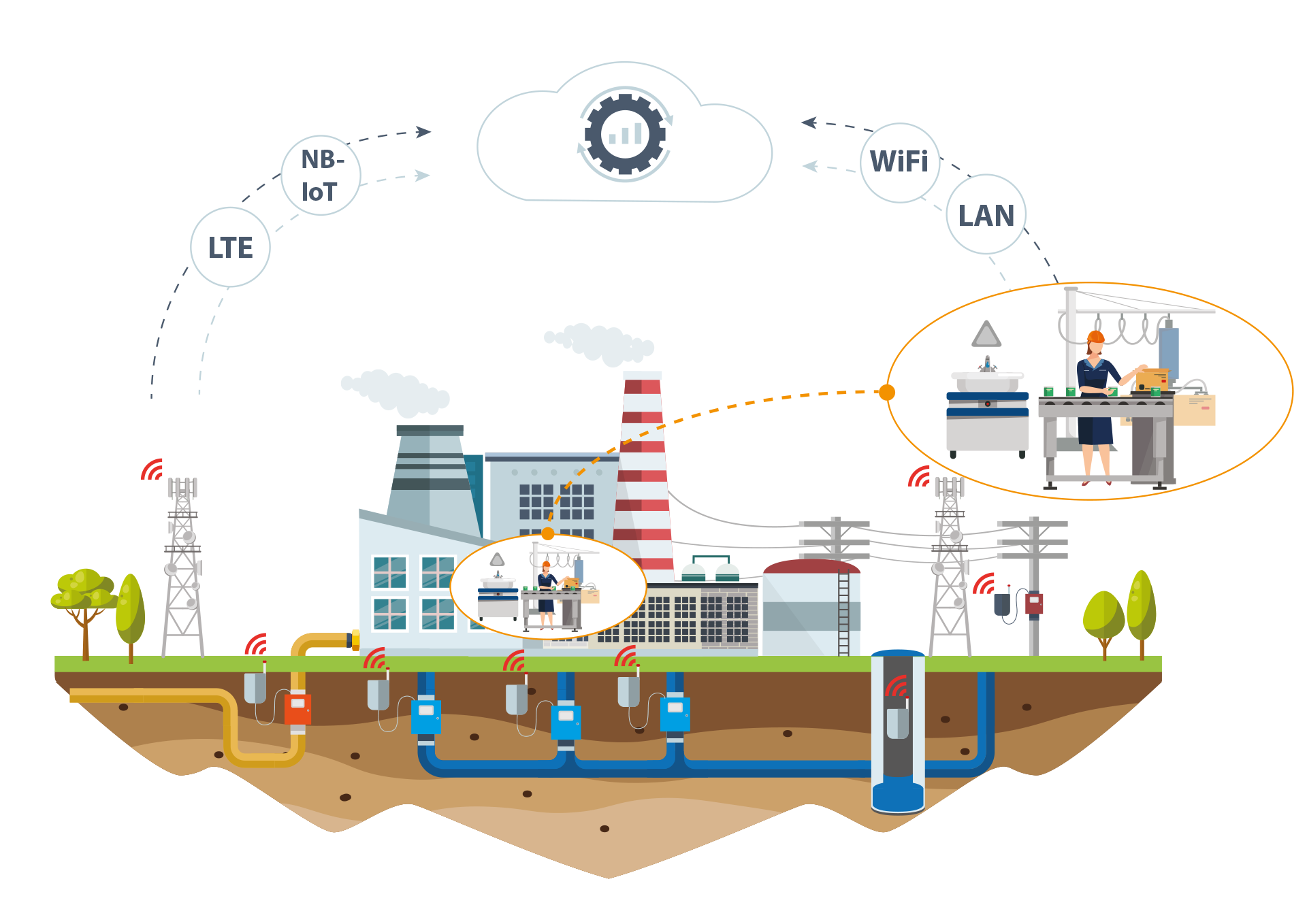

EM-TOOL, based on the proven Siemens platform, allows you to integrate most of your measurement devices into one unified monitoring system. A clear presentation of data in various combinations provides a strong tool to support the control process and reduce costs.

BENEFITS

- all media aggregated in one place

- complete consumption record

- improved cost identification

- detection of anomalies

- possibility of combined analysis for production data and utility consumption

- support for carbon footprint labelling

- more efficient plant utilization

- cost optimization

- gradual implementation

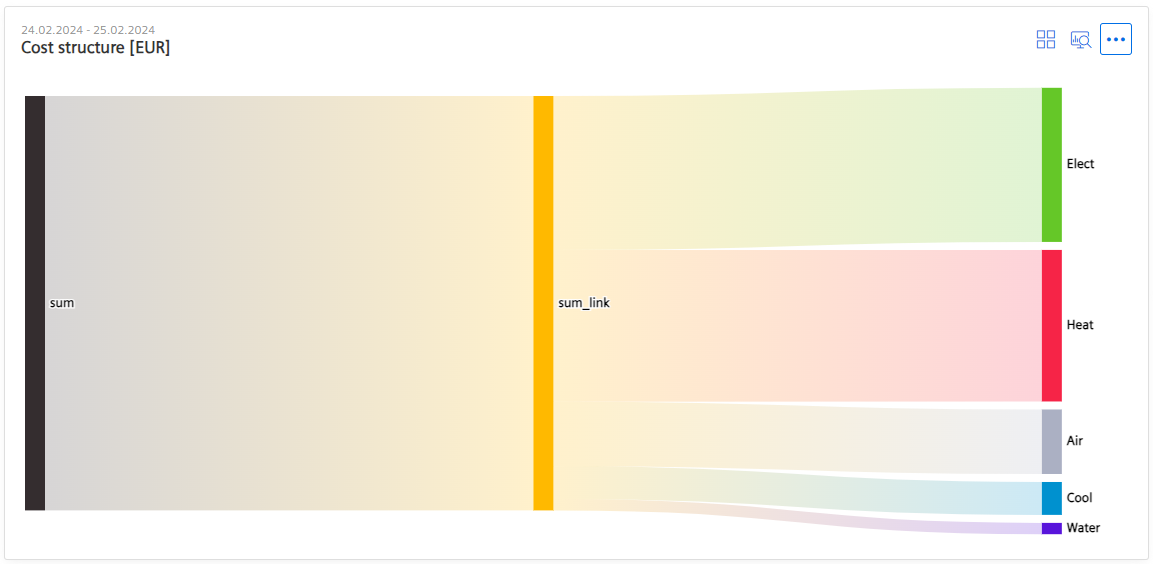

CONSUMPTION DOCUMENTATION

- presentation of all cost sources – electricity, water, gas, steam, etc.

- individual and summary reports

- diversified statements – medium, production line or whole plant

- preliminary analysis and presentation of common features

- marking of typical anomalies

- graphical presentation of statistics

- Sankey chart illustrating consumption distribution

- extensive filter system

- automatically generated reports with the possibility of sending to an e-mail address

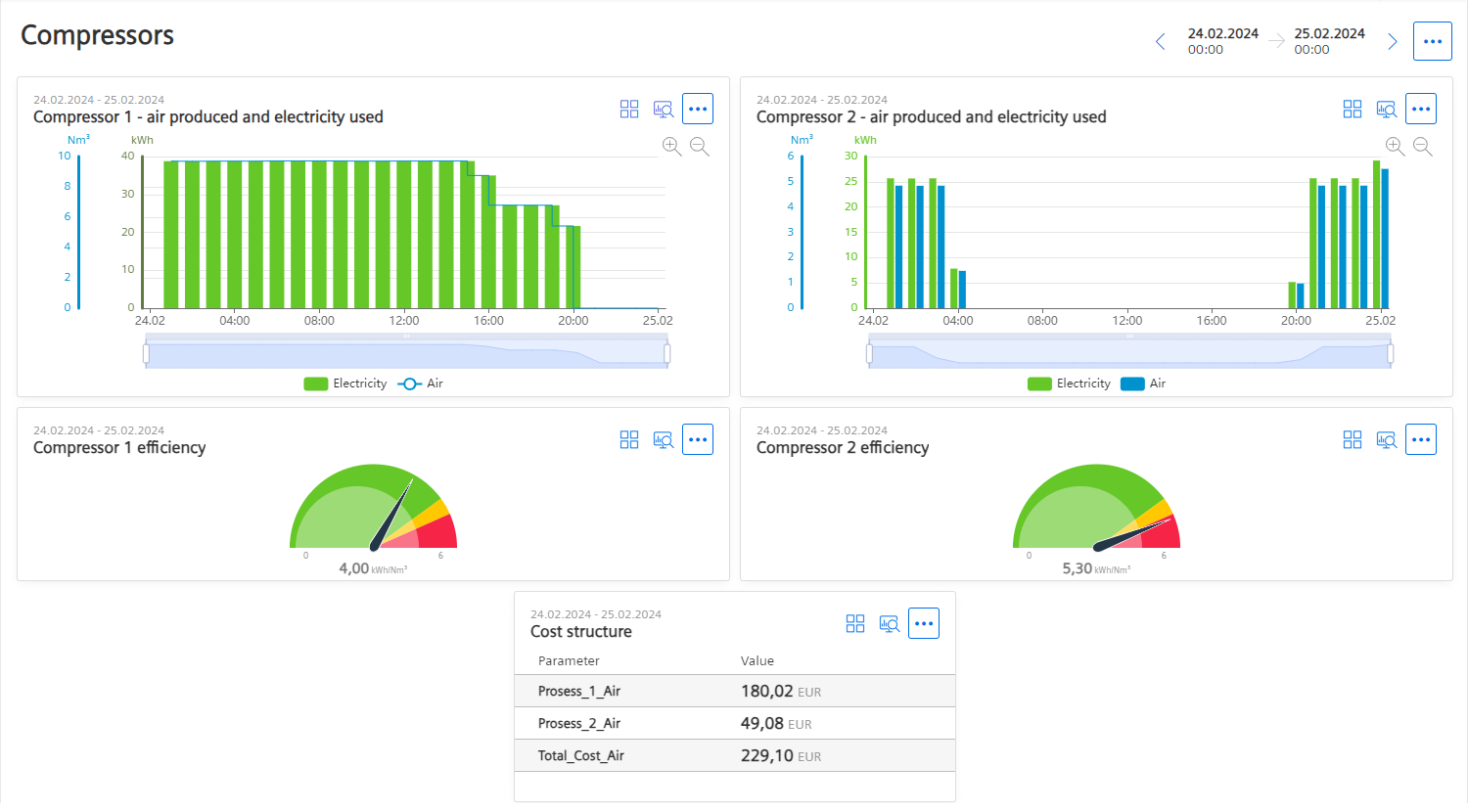

ANALISYS AND OPTIMIZATION

- data analysis for a single medium and from a plant structure perspective

- time-based presentation of change tendencies

- cost calculation

- determination of KPIs

- comparative analysis for a time period or product batch

- determination of the plant’s CO2 emissions

ADVANCED FEATURES

- advanced analysis of total costs linked to production data

- graphical presentation of KPIs for a selected product batch

- chart of media consumption by production batch

- product batch rank based on efficiency

- real vs. projected consumption based on a mathematical model

- advanced filtering and presentation possibilities

- implementation of the power guard feature

UNIVERSAL TECHNICAL SOLUTION

- dedicated to many user groups

- applicable to new and existing installations

- based on Siematic Energy Manager platform

- integration of measuring devices of most manufacturers

- covers all types of media required for the production process

- installation on new or existing hardware

- professional support in expanding an existing control system

- data backup on-site or in the cloud

Would you like to find out more about our smart CIP and EM tools for optimising your cleaning processes and analysing energy and media consumption? Get in touch with us today.