Easy to locate: RFID tracking

Radio Frequency Identification (RFID) technology

Whether beverage crates, kegs, parcels or entire pallets – Radio Frequency Identification (RFID) makes it clear within seconds exactly where each item is located.

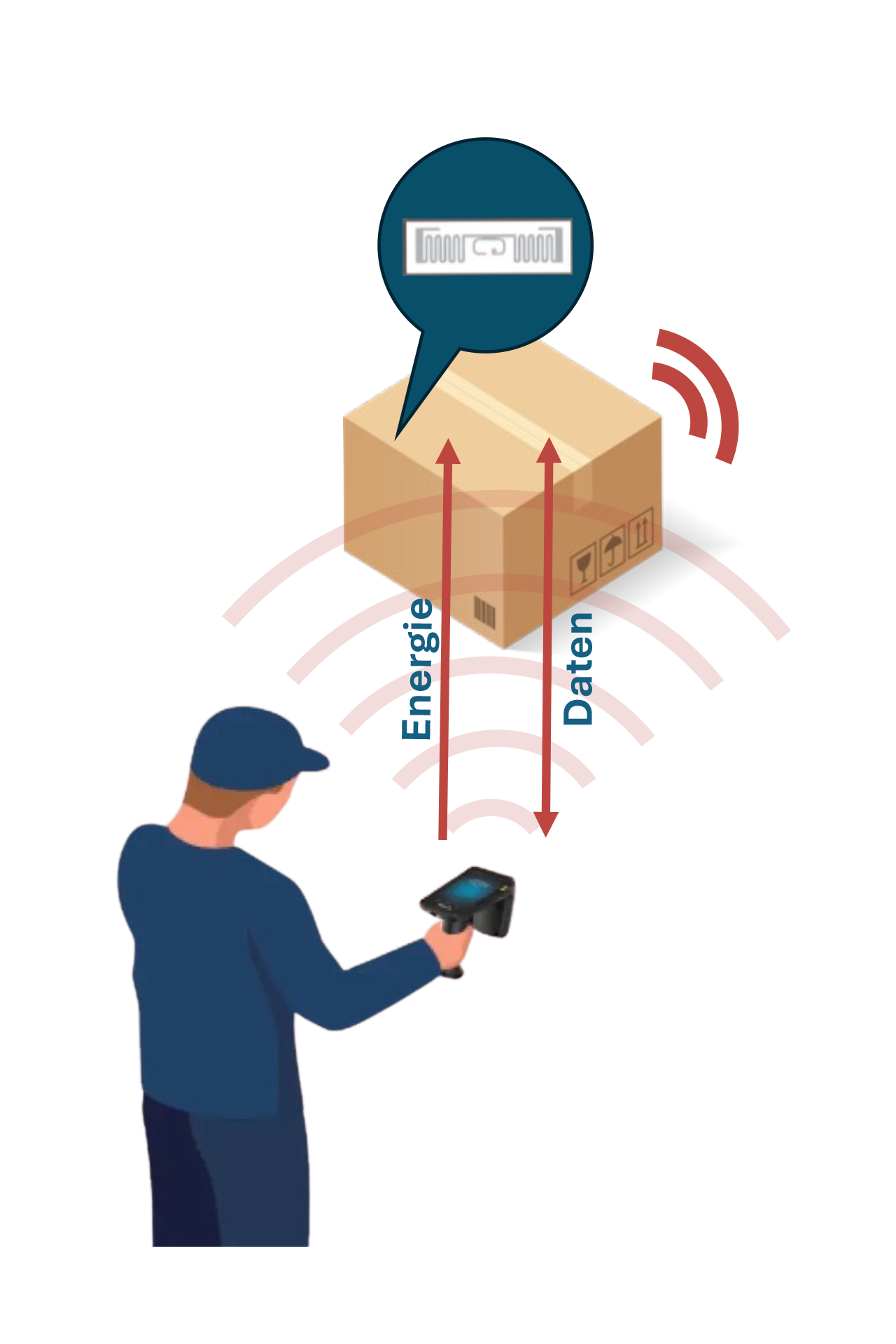

Wherever products, containers or components are on the move, RFID creates transparency – from the beverage industry and agriculture through to healthcare, food production and logistics. Each object is fitted with a tiny, passive chip that is automatically detected via radio waves – without any line of sight and over distances of up to ten metres. The chip can be positioned almost anywhere, even inside an object, and is still reliably identified. Whether on forklift trucks, conveyor systems or at gates, readers capture hundreds of tags simultaneously and store the data centrally – virtually on the move.

Our colleague Florian Kringe, Project Manager Auto ID Systems, explains the benefits: “This means fewer losses, less effort and fewer sources of error. Instead of counting items individually, entire incoming goods shipments are captured automatically, logged and documented. Once tagged, the intelligent object can be clearly identified at all RFID stations and tracked throughout the entire process. This also makes it possible to trace exactly which goods come from which supplier – an important factor for deposit accounting or documenting the condition of goods. Stock levels, circulation quantities, goods locations and other relevant information can also be recorded – effectively creating a complete lifecycle record for each object.”

RFID is also a key enabler for greater sustainability. Precise tracking of material flows helps to avoid overproduction and material shortages, enables more targeted recall campaigns and ensures a far more efficient use of resources. “RFID doesn’t just deliver data – it creates a completely new awareness of processes,” says Florian Kringe. “Every item remains digitally visible, allowing workflows to be optimised far more efficiently.” In short: a small chip with a big impact.

Technical highlights

No line of sight required – unlike barcode systems, for example. The chip can even be located inside an object or behind packaging and is still detected reliably. Data capture is significantly faster, and multiple objects can be read simultaneously.

RFID transponders are maintenance-free, as they do not require their own battery. They draw the necessary energy directly from the radio waves emitted by the reader. This makes them particularly reliable and durable – a clear advantage for a wide range of applications in industry, logistics and retail.

RFID doesn’t just deliver data – it creates a completely new awareness of processes. Every item remains digitally visible, and workflows can be optimised far more efficiently.

Florian Kringe, Project Manager Auto ID Systems, SCHULZ Systemtechnik