New technologies conquer empties logistics

Food & Beverage Expert Days 2024

New technologies for more sustainability and digitalisation: This is the focus of the current series of Food & Beverage Expert Days launched by Siemens. True to the motto “From the industry for the industry”, experts from production and plant and mechanical engineering reported on trends and developments for greater efficiency in automation.

In the conference room centre at Münster-Osnabrück Airport, visitors were welcomed by many interesting presentations on standardisation strategies, current legislative changes in the food industry, recycling and sustainable packaging solutions. The accompanying exhibition also provided the perfect opportunity to network, talk shop and gather information.

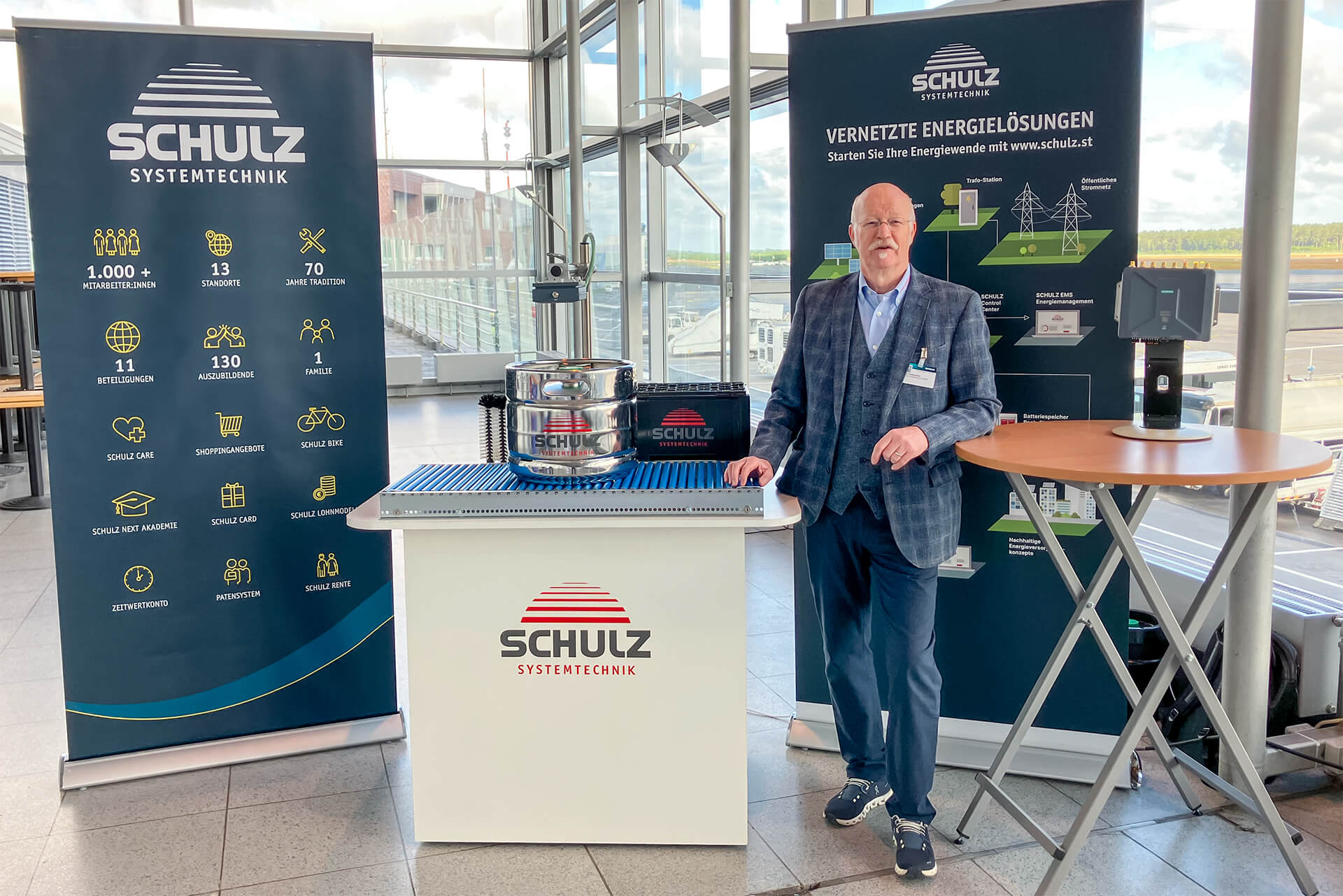

Smart identification systems on the rise: Our colleague Horst Rademacher shows the versatile application.

Innovative empties supply chain monitoring using the example of a brewery

Our colleague Horst Rademacher was also on site. The expert in RFID technologies gave a presentation on industrial identification systems together with Markus Sonnenschein from Siemens. As a Siemens Solution Provider, we rely on the manufacturer innovative and globally proven products for many automation solutions. We are expanding our cooperation in the area of identification systems for industry and are working together on intelligent solutions for process optimisation.

First, the portfolio around the world of SIMATIC IDENT was presented in numerous application areas. This was followed by a specific example in beverage reverse logistics. RFID (radio-frequency identification) technology can fully maximise its advantages in this area. This is done completely by attaching RFID transponders in the beverage crate, by using RFID labels on the empties transport pallet, in beer kegs and event materials. The advantage: Maximum efficiency through transparency. Important information that can be used not just by logistics, but also by sales, marketing, IT, controlling and production divisions.

Central component of digitalisation

RFID makes objects intelligent and can be used for digitalisation projects. This allows intralogistics processes to be optimised in many areas.

For empties logistics, this means: A wide variety of crates, kegs and other products can be recorded and added to the required destination in the shortest possible time.

Our colleagues in Kassel have a wealth of expertise in this area. They carry out feasibility studies and create detailed process analyses. Building on this, they then realise detection systems, develop the software and integrate the systems at our customer premises.

Do you have questions about our intelligent RFID solutions? Please feel free to contact us.

Our Kassel site, specialising in identification and sorting systems for the beverage industry, expanded its portfolio to include supply chain management and AutoID systems.

Horst Rademacher, Senior Consultant RFID Technology, SCHULZ Systemtechnik