Air conditioning systems

Reliable cleaning, ventilation and cooling for industry and agriculture

EMMI Emission Minimizer for the industry

We are your expert when it comes to clean to the air. For the industrial sector, we offer the installation of various EMMI Emission Minimisers.

Depending on the requirements, a wide variety of substances must be removed from the air extraction, including dusts, odours, germs or harmful gases. A heavy-duty process exhaust air flow, for example, must be treated differently than room air extraction. We will develop an individual EMMI Emission Minimizer for you that fits your application perfectly.

Benefit from our specialisation in particularly energy-efficient cleaning systems. These stand-alone systems are highly reliable. Regular support and maintenance after installation by our technical staff – also through location-independent support – will ensure you a high level of operational reliability.

EMMI Emission Minimizer: With SCHULZ from a single source

- Monitoring of the approval procedure

- System planning

- Mounting and installation of the system

- Commissioning

- Training

- Maintenance

Cleaning performance: Depending on the requirement, for example

- • At least 95% NH³

- • At least 95% H²S

- • Less than 500 GE/m² (no raw gas smell perceivable)

Cleaning performance:

- At least 90% NH³

- At least 70% dust

- At least 90% fine dust

- At least 50% odour

EMMI PIG – EXHAUST AIR CLEANING FOR YOUR PIG FARM

Exceptionally high filter performance on the smallest surface area: more efficiency for farming

You can benefit from our efficient and reliable exhaust air cleaning systems also in professional pig farming. Our latest highlight is EMMI Pig – an exhaust air scrubber that we have developed especially for pig farming systems using no floor litter.

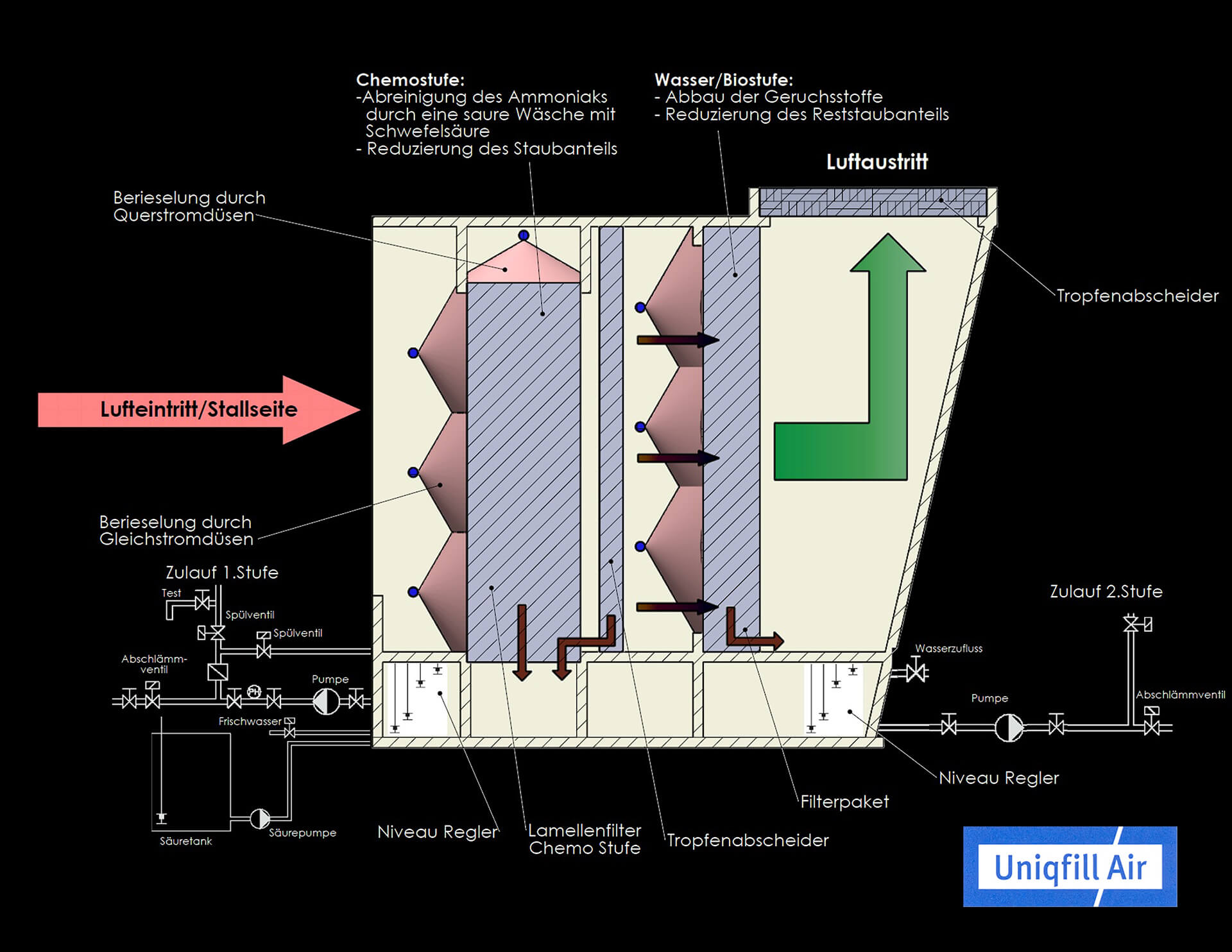

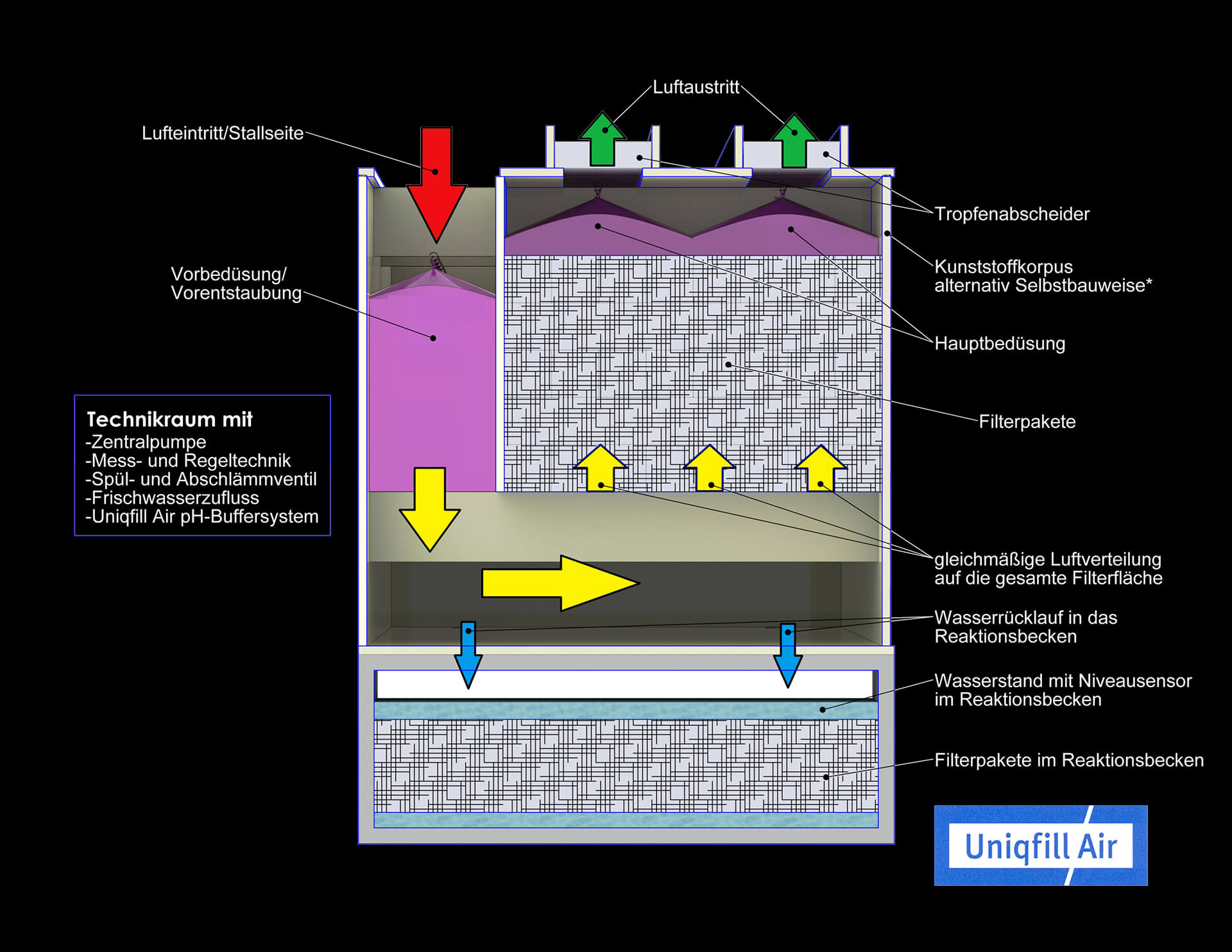

The system is a two-stage exhaust air scrubber operating wet chemically and using acid as well as downstream bio-scrubbing to remove dust, ammonia and odour by means of overhead ventilation. Downstream of both cleaning stages, a droplet separator minimises aerosol discharge during exhaust air cleaning as well as reducing germ discharge from the barn.

Leveraging its uniquely high filter surface load of 5,000 m³/(m²h), EMMI Pig boasts impressive performance. As a result of this, the system features an extremely compact, space-saving and flexible design. In this way, one can significantly reduce investment costs and enjoy greater cost-effectiveness and efficiency.

HOW IT WORKS:

Exhaust air is extracted by fans from the stable compartments and pressed evenly through the air scrubber. To do so, the air scrubber operates fully automatically. In the first step (chemical step), the stable air contaminated by ammonia and dust is cleaned by means of an “acidic” wash (sulphuric acid). The odorous substances are removed in the downstream second stage (bio-stage).

Therefore, the cleaning performance achieved accounts for

- at least 86% and 80% as to ammonia (NH³)

- and dust respectively,

- with odour minimised to below 300 GE/m³, no perceivable raw gas smell in clean gas

- and the benefit of very low amounts of wastewater

Our exhaust air cleaning system “EMMI Pig” is suitable for reducing emissions of dust, ammonia (including nitrogen removal) and odour in the exhaust air flow from pig farming systems with no floor litter by means of overhead ventilation.

Upsides in detail:

- Customised construction designs tailored to animal numbers (containers also available)

- Clear description of plant operation through electronic operating logbook

- Low pressure losses through fluid-dynamically optimised exhaust air ducts

- Remote queries and remote maintenance are possible

- Use of proven industrial components

- Low volumes of wastewater resulting in reduced transport and storage costs

- Use of water containing ammonium sulphate (A SL) as a high quality fertiliser

- Reduction of energy costs as a result of outstanding system management

- Custom-tailored design and thus investment cost abatement

- Minimised service costs thanks to high operational safety

- Less intensive maintenance

Further air purifiers for pig farming

The following exhaust air purification systems for pig farming complete our broad portfolio of DLG-certified systems.

Exhaust air scrubber Chemo+ 5880

CLEANING PERFORMANCE:

- At least 85% ammonia (NH³)

- At least 95% dust reduction

- Odour minimisation to below 300 GE/m³ and no perceivable raw gas smell in clean gas

Exhaust air scrubber BioCombi 6178

Cleaning performance:

- At least 92% ammonia (NH³)

- At least 95% dust reduction

- Odour minimisation to below 300 GE/m³ and no perceivable raw gas smell in clean gas

Promote the efficiency of your agriculture with intelligent air conditioning systems

Professional air conditioning technology in agricultural animal husbandry includes the control and monitoring of ventilation, heating and humidification systems. We build the foundation for optimal conditions in the animal house with our versatile systems. All functions are, of course, ideally coordinated – for intelligent farm management and better animal welfare.

#1 Ventilation

Depending on the type of animal and the climatic and structural conditions, we offer various supply and exhaust air systems that are individually tailored to your plant. A wide range of functions are available to you to control the air conditioning in pig and poultry houses.

For each compartment or barn, it is possible to evaluate temperatures, humidity, negative pressure, CO² and NH³ content in order to optimally coordinate ventilation, heating, supply air and exhaust air. A climate curve adjusts all parameters to the respective age of the animals.

Our know-how in detail

- Fully insulated wall outlet for optimal climate in all climate zones

- Exact and optimal air flow in cold weather conditions

- Direct supply of fresh air at high ambient temperatures

- Constant vacuum for consistent airflow velocity

- Easy installation, quick and thorough cleaning and disinfection

- Applicable as a wall mounting valve to fit the layer of stones or as a flanged valve, expandable with a mounting frame for any wall thickness

#2 Heating

If you heat optimally, this has a positive influence on the performance of the animals. At the same time, you noticeably increase animal welfare and health. In many geographical areas, heating is indispensable. SCHULZ offers various systems considering optimal energy costs:

- Underfloor heating

- Open and closed combustion chamber

- Warm water convectors

- Hot air blower

#3 Cooling

In addition to the feed and watering, for example via our intelligent feeding systems, temperatures play an important role in animal husbandry. Especially on hot summer days, it is important to cool the air in the barn. Benefit from our various air conditioning systems that create optimal temperatures on hot days and thus ensure more animal welfare.

Our know-how in detail

- Effective cooling in summer

- Pleasant air conditioning in the barn due to dust binding

- Fast, thorough cleaning and disinfection

- Nebulisation of enzymes

- Control of high-pressure systems, pad cooling systems and rotary coolers

Would you like more information about our air purification and air conditioning systems, or would you like to learn more about SCHULZ? Contact us today – we look forward to your enquiry!